What Equipment Is Used in Boring Services

Boring services play a very important role in many industries such as construction, mining, manufacturing, and civil engineering. Whether it is for building strong foundations, testing soil strength, or creating precise holes in metal or concrete, boring makes projects more accurate and reliable. But the success of boring services depends largely on the type of equipment used. Each piece of equipment is designed to handle specific tasks, materials, and project requirements.

In this blog, we will explore in detail the equipment used in boring services, how each type works, and why it is important. This simple guide will help you understand boring equipment better, even if you are new to the topic.

Note: Boring services in Dubai provide precise and efficient solutions for creating deep foundations, tunnels, and accurate holes in construction and industrial projects, ensuring strength and reliability.

Introduction to Boring Equipment

Boring is the process of enlarging or creating holes in soil, rock, or hard materials. The equipment used in boring can range from small machines for light jobs to heavy-duty drilling rigs for large construction projects. The choice of equipment depends on the type of project, the ground conditions, and the depth or accuracy required.

Without the right equipment, boring services would take longer, cost more, and may not achieve the desired results. This is why professional boring service providers invest in advanced machines and tools.

Categories of Boring Equipment

Boring equipment can be divided into several categories. These categories are based on how the machine works, the material it handles, and the purpose it serves. Let us explore them step by step.

Heavy-Duty Boring Machines

These are large machines used for construction and infrastructure projects. They are designed to handle heavy loads and work on tough materials such as concrete, steel, or rock.

Horizontal Boring Machines

Horizontal boring machines are widely used in industrial projects. They work by rotating a tool horizontally into the material to create or enlarge holes. These machines are especially useful for large parts where vertical machines may not fit.

-

They provide high accuracy.

-

They can handle large and heavy objects.

-

Commonly used in manufacturing large machinery parts.

Tunnel Boring Machines (TBMs)

One of the most well-known heavy-duty boring machines is the tunnel boring machine. These machines are massive in size and used to create tunnels for railways, roads, or water pipelines.

-

They cut through rock and soil efficiently.

-

They reduce manual labor and make underground work safer.

-

Equipped with conveyor systems to remove debris.

Light and Medium Boring Equipment

Not all boring projects need massive machines. For smaller construction or repair projects, light and medium-sized boring equipment is enough.

Portable Boring Machines

Portable boring machines are smaller and can be carried to the project site. They are used for on-site repairs, such as enlarging holes in pipes, shafts, or mechanical parts.

-

Easy to set up and transport.

-

Saves time in maintenance jobs.

-

Useful in industries like shipbuilding and mechanical repair.

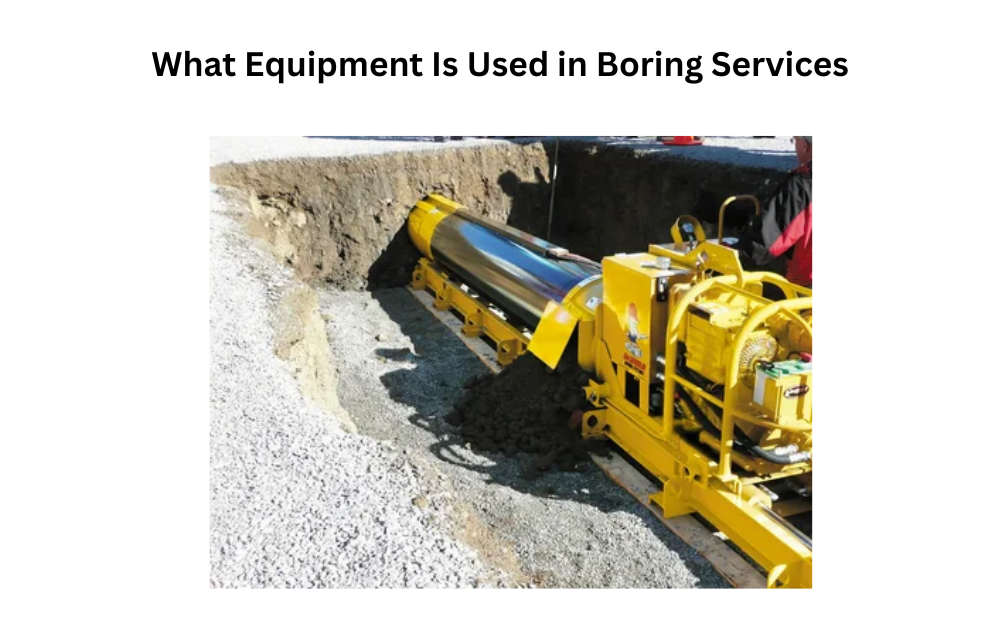

Auger Boring Machines

Auger boring is often used for installing pipelines under roads or railways without disturbing the surface. The machine uses a rotating auger (screw-like tool) to remove soil while pushing the pipe into place.

-

Cost-effective method for underground pipeline installation.

-

Reduces traffic disturbance.

-

Works well for short to medium distances.

Precision Boring Equipment

In industries where accuracy is critical, precision boring machines are used. These machines provide fine control to achieve exact measurements.

Jig Boring Machines

Jig boring machines are designed for extremely precise hole placement. They are mainly used in tool-making and aerospace industries.

-

Provide accuracy up to fractions of a millimeter.

-

Used for creating holes that require exact positioning.

-

Common in high-tech manufacturing processes.

CNC Boring Machines

Computer Numerical Control (CNC) boring machines are advanced machines operated by computers. They allow operators to program exact dimensions and automatically perform the boring operation.

-

Reduces human error.

-

Suitable for mass production.

-

Delivers both speed and accuracy.

Support Equipment in Boring Services

Apart from the main boring machines, several support tools and equipment are also required to make the process smoother and safer.

Drill Bits and Cutting Tools

The quality of boring depends heavily on the type of drill bit or cutting tool attached to the machine.

-

Carbide drill bits for hard metals.

-

Diamond-tipped tools for cutting through rock and concrete.

-

Standard steel tools for softer materials.

Power Systems

Boring machines need a reliable power source to run. Depending on the size and design of the machine, power systems may include:

-

Hydraulic systems for heavy-duty machines.

-

Electric motors for precision boring equipment.

-

Diesel engines for portable machines in remote areas.

Measurement and Alignment Tools

Precision is the key to boring services, so alignment tools are used to ensure that holes are straight and accurate.

-

Laser alignment systems for high accuracy.

-

Dial indicators for checking measurements.

-

Leveling devices to keep machines steady.

Safety Equipment in Boring Services

Safety is always a top priority in boring projects. The equipment itself is powerful and can be dangerous if not handled correctly. To protect workers, safety equipment is used.

Protective Gear for Operators

-

Helmets, gloves, and safety shoes.

-

Ear protection for loud machines.

-

Goggles to protect eyes from dust and debris.

Machine Safety Features

-

Emergency stop buttons.

-

Protective covers on moving parts.

-

Automatic shutdown in case of overheating.

How Boring Equipment Improves Project Efficiency

The use of advanced boring equipment has changed the way projects are completed today.

-

Faster results – Machines can complete in hours what would take days manually.

-

Cost savings – Reduced labor costs and fewer mistakes.

-

Better accuracy – Machines ensure holes are positioned and sized correctly.

-

Improved safety – Workers are less exposed to dangerous manual work.

Choosing the Right Boring Equipment

Every project is different, so choosing the right equipment is very important. Factors that affect the choice include:

-

The type of material (soil, rock, metal, concrete).

-

The size and depth of the hole required.

-

The level of accuracy needed.

-

The budget and timeline of the project.

Professional boring service providers study the project requirements before selecting the right machine.

The Future of Boring Equipment

With advancements in technology, boring machines are becoming smarter, faster, and safer.

-

Automation – More machines are being operated through computers.

-

AI integration – Artificial Intelligence is being used to make machines self-correct errors.

-

Eco-friendly designs – New machines consume less energy and reduce environmental impact.

The future promises even better equipment that will make boring services more efficient and sustainable.

Conclusion

Boring services are essential for many industries, and the equipment used in these services plays a big role in their success. From heavy-duty tunnel boring machines to portable boring tools, each piece of equipment has its unique purpose. Support tools like drill bits, alignment systems, and safety devices ensure that projects are completed accurately and safely.

By choosing the right equipment, boring service providers can save time, reduce costs, and deliver reliable results. As technology improves, boring equipment will continue to become more advanced, helping industries achieve even greater efficiency.

Raysun Techno Industries LLC is spearheading metalwork technology with its sheer expertise and dedication. With the high-end technologies at their disposal, our expert engineers are capable of providing an array of services ranging from metal welding, machine shop and electromechanical to surface treatment and inspection. Be it for machining or welding, our team is always equipped to provide consistent and premium services to our vast clientele dealing in the Oil and Gas industry.

For more insightful articles related to this topic, feel free to visit: mifinder.co

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness